Lifting systems

TC slot cutting system is an extremely flexible and efficient solution for slotting of anodes. The system can make one, two or three slots with height variation.

Saw blades are diamante tipped with exchangeable cutters. Expected cutter consumption is one cutter each 10.000 anodes. Even better lifetime can be expected when anode temperature is on lower level. Anode temperatures above 250ºC is not recommended.

The TC slot cutting system can make continuous or interrupted slots. Slot shape can be angled or curved according to customer specification.

The TC system slots the anodes outside conveying system. This minimizes problems for production when system is down for service or maintenance.

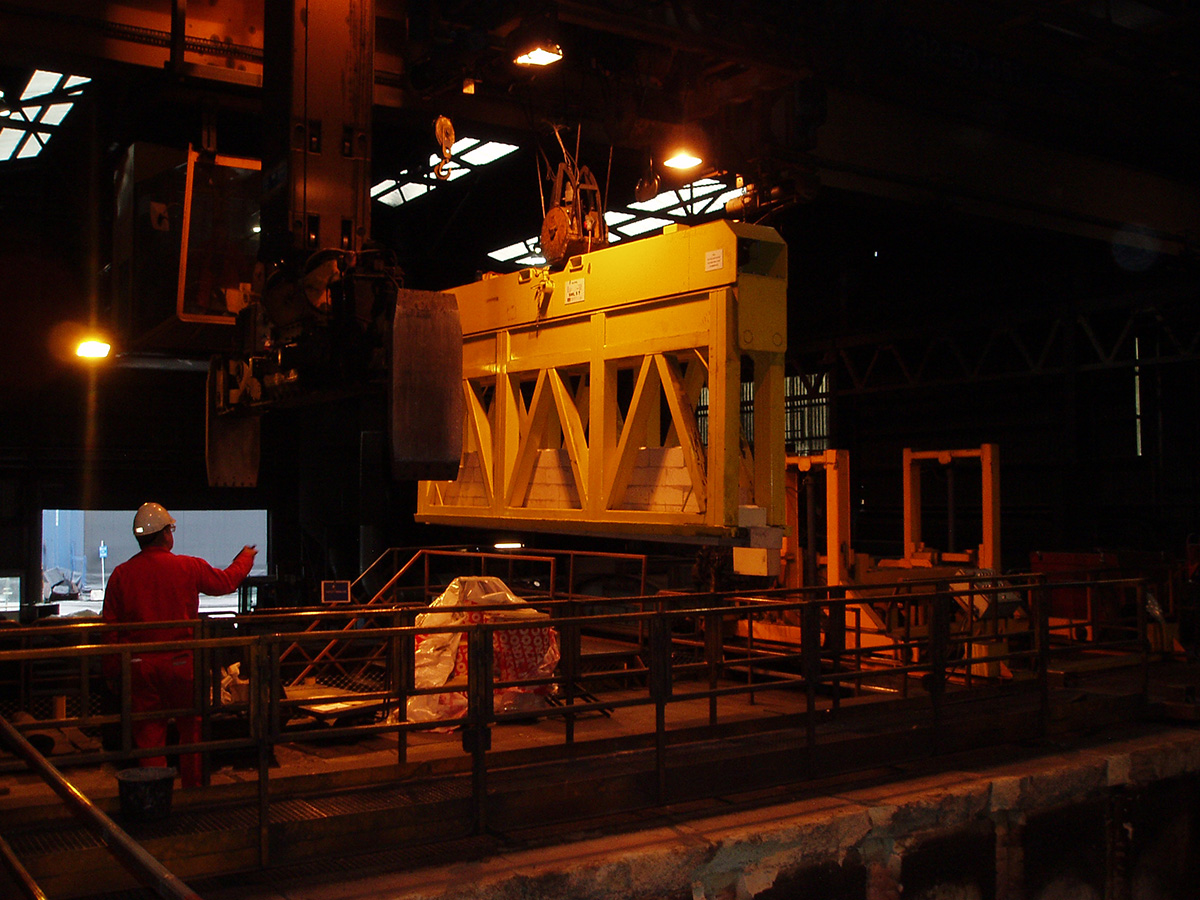

TC supplies special designed systems for demolishing and rebuilding of flue walls. Flue walls may be handled as sections or complete units. Depending upon wall design adaptions the starter block may have to be done.

The systems are mechanically or hydraulic operated. All systems are based upon TC’s well reputed tong design with a wide range of built in safety options.

Advantages:

• Heavy duty design

• Flexible systems

• Reliable in operation – low maintenance.

• Safe and efficient handling

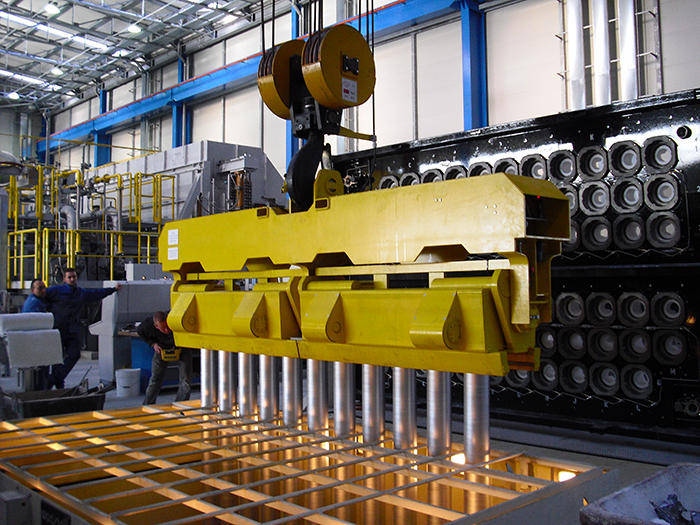

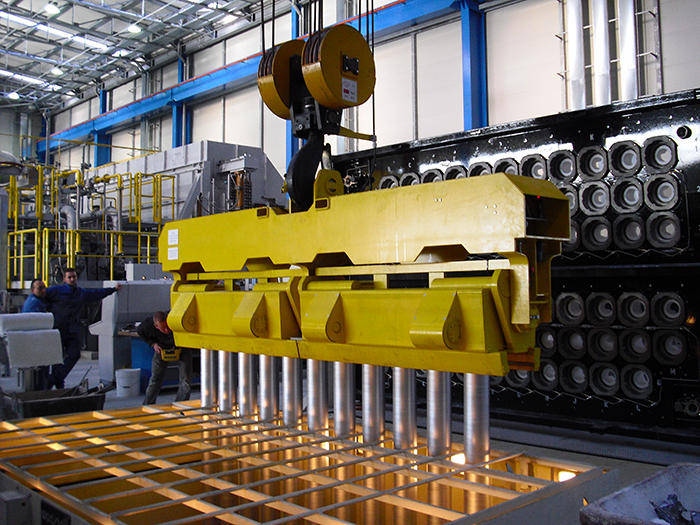

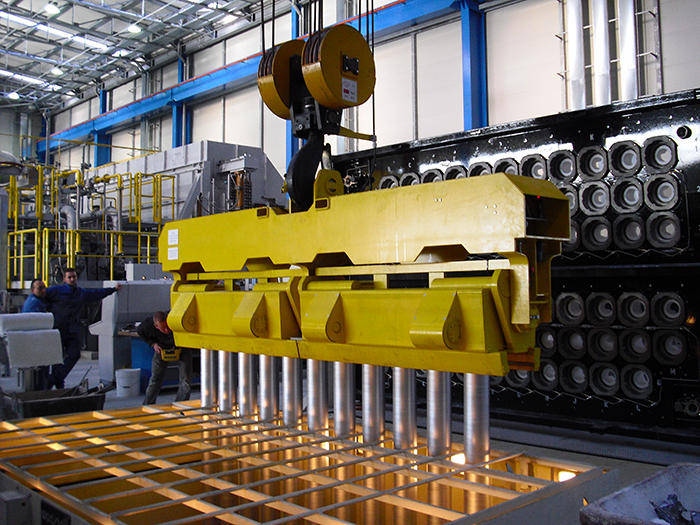

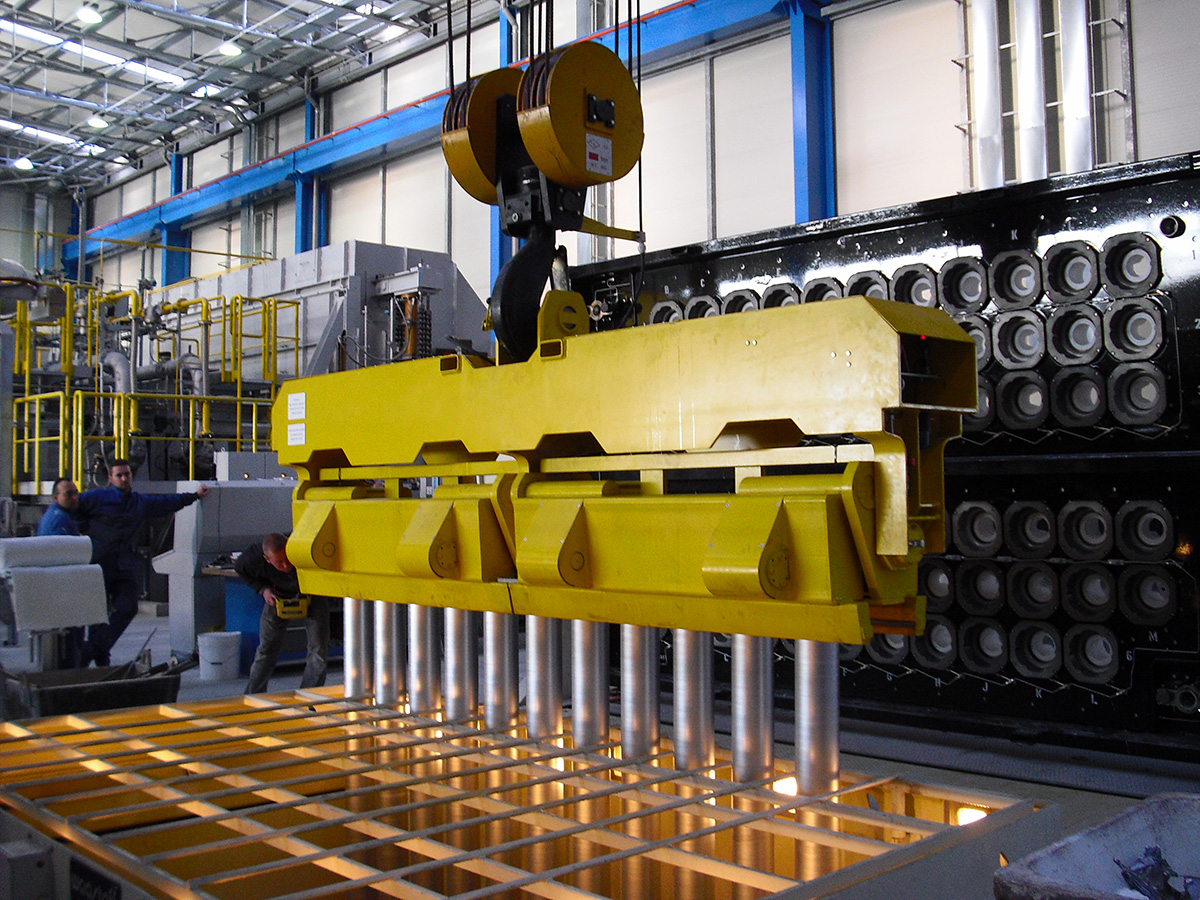

TC has a number of alternative systems for anode handling. This is for single anode, double anode, two anodes in height or a complete row of anodes. The systems will be adapted to anode size, capacity and customer requirements.

The systems are mechanically or hydraulic operated. Mechanical tongs has all automatic locking devices giving automatic operation.

Advantages:

• Heavy duty design

• Flexible systems

• Reliable in operation – low maintenance.

• Compact and easy to handle

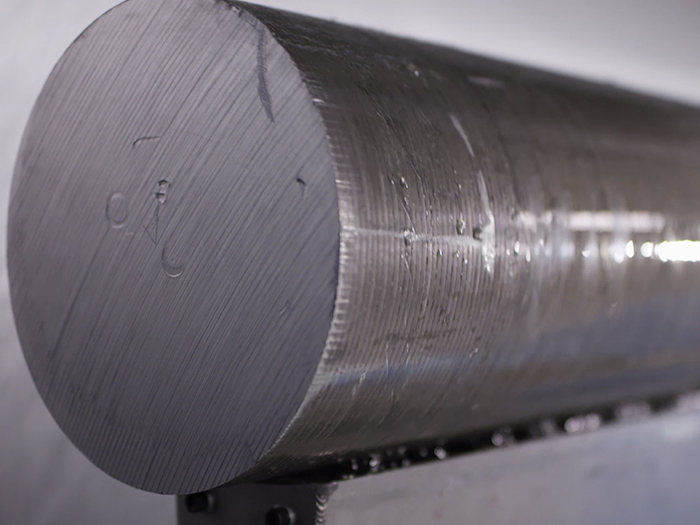

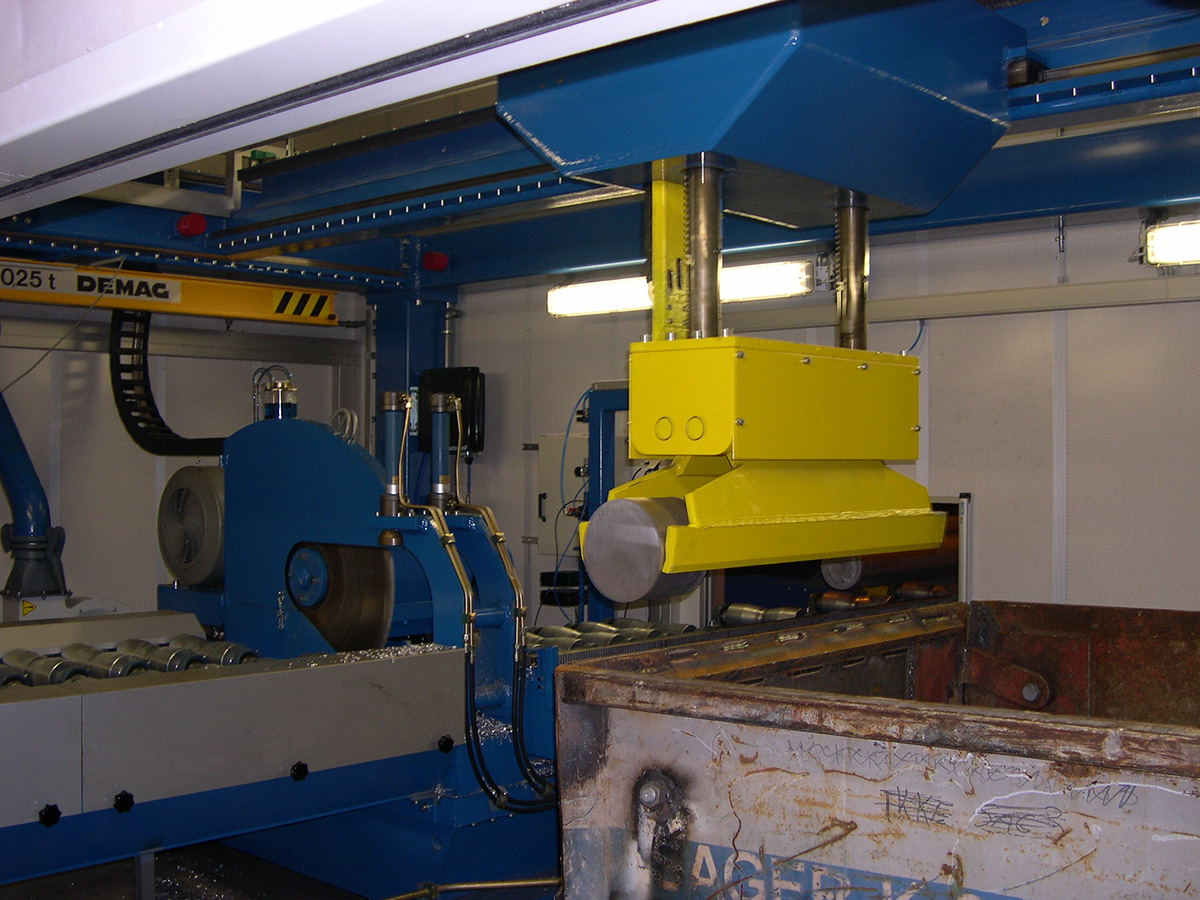

TC supplies state of the art system for centre crack or 100 % ultrasonic testing of aluminium extrusion billets. The system is a “simulated” submerged system. This means that the part of the billet tested is submerged in water.

This system gives a stabile environment for testing excluding possible errors due to missing water contact, bubbles or surface imperfections.

The system is based upon the latest available hardware and custom made software for data processing.

The system is designed with sensor clusters giving safe and efficient testing at high speed. For centre crack testing speed may be up to 500 mm/sec., while 100 % testing will require more than 1.5 min for 7.5 m length. Test cycle increases by increased billet diameter.

TC supplies special designed systems for demolishing and rebuilding of flue walls. Flue walls may be handled as sections or complete units. Depending upon wall design adaptions the starter block may have to be done.

The systems are mechanically or hydraulic operated. All systems are based upon TC’s well reputed tong design with a wide range of built in safety options.

Advantages:

• Heavy duty design

• Flexible systems

• Reliable in operation – low maintenance.

• Safe and efficient handling

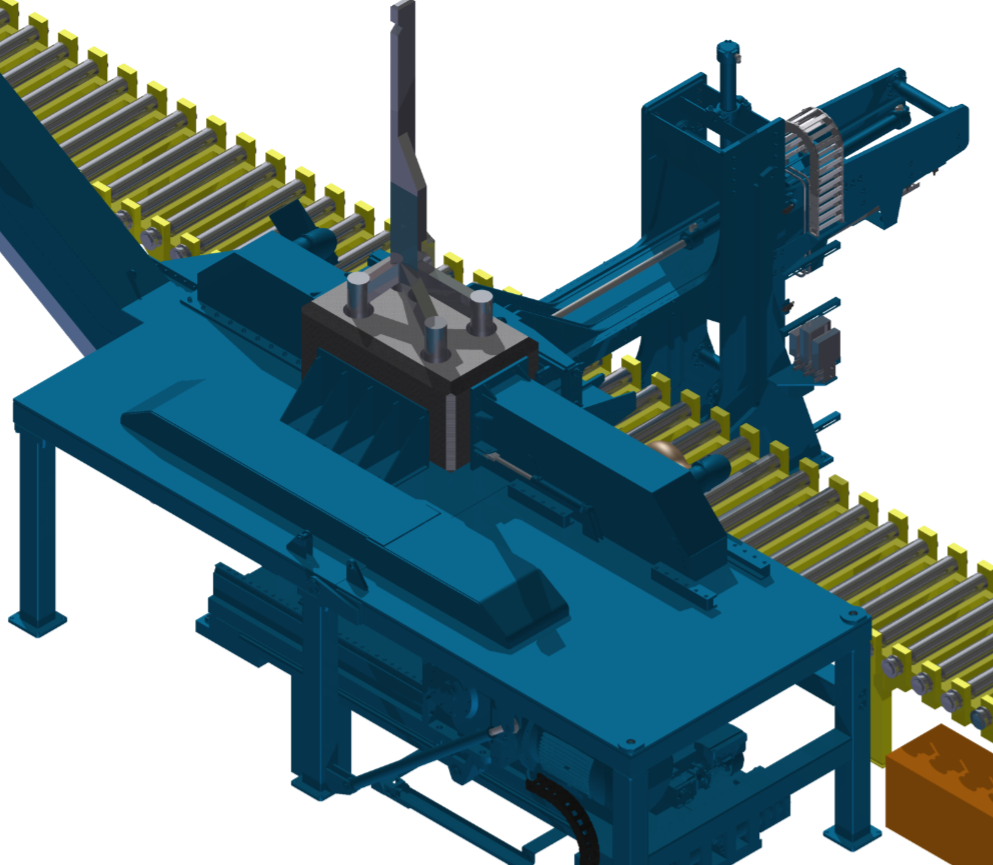

TC Engineering AS is a supplier of automatic handling systems for aluminium extrusion billets. Our systems are customer adapted to fit product range. The systems are based upon use of standard components from well reputed suppliers, and special designed yokes and handling devices from TC.

Servo and frequency control of all movements gives soft and efficient handling.

Advantages:

• Heavy duty design

• Huge flexibility

• Reliable in operation

• Modern and well designed

• High speed and soft operation

TC Engineering AS is a supplier of complete cutting and handling systems for aluminium extrusion billets. Our stacker system is extremely flexible with regard to diameter and length variations.

The stacker system handles single and double packages, short and long billets and a huge variation in diameters. Servo operation gives a very clean and speedy system with low maintenance.

Advantages:

• Heavy duty design

• Huge flexibility

• Reliable in operation

• Modern and well designed

• Easy operation and maintenance

Specially adapted marking and labelling system for single billets or bundles. Direct marking or labelling. Labelling on package or straps.

TC can integrate a number of systems for product marking. This may include ink-jet marking, hard stamping, dot matrix marking or labelling. Labelling may be added to the product or to the strap.

TC Engineering AS is a supplier of complete cutting and handling systems for aluminium extrusion billets. Our automatic strapping system is extremely flexible with regard to package shape and size.

The strapper head and spacer feeding is electric operated. This gives accurate and reliable operation. Strapping head from Signode with polyester straps.

Advantages:

• Heavy duty design

• Huge flexibility

• Reliable in operation

• Modern and well designed

• High speed and accuracy

TC Engineering supplies various solutions for conveying and handling of billets.

A heavy duty design is used for all components. All systems are adapted to meet the customers requirements and can be modified to match different products and ranges.

Lay Down Units

Roller Conveyors

Chain Conveyors

Elevators

Pick & Place Units

Shuttle Systems

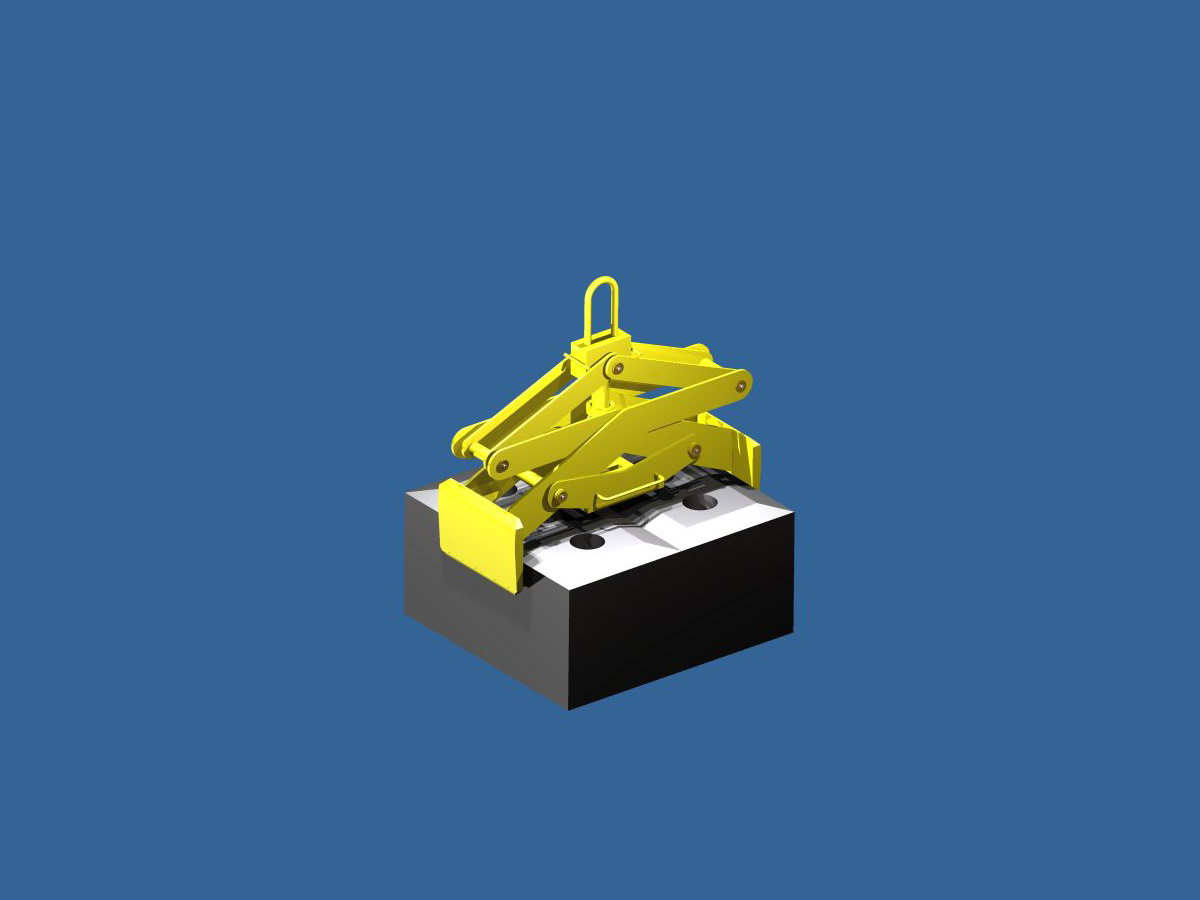

The TC Slab Bar Tong is designed for handling of slab and T-bars by grabbing in the end section. The TC units has a hugh range and can normally handle the complete range with one unit. The TC units has low height and leaves very small handling marks.

With the TC Slab Bar Tong you may handle slabs and T-bars vertically and horizontally using the same unit.

Advantages:

• Huge range

• Low height

• Extra mechanical safety system available

• Reliable in operation – low maintenance.

• Service and maintenance system available

• Hugh number of systems in operation

TC Engineering AS is a supplier of complete cutting and handling systems for aluminium extrusion billets. Our saw system is supplied in two sizes, the largest one going up to ø 458 mm.

The saw may be used with segmental or carbide tipped blade. The system is supplied with frequency converter for blade speed and servo feeding. Alu Lube lubrication system for saw blade.

Advantages:

• Heavy duty design

• Flexible optimisation

• Reliable in operation

• 3 years maintenance cycle.

• Easy to install and operate

The TC Slab Bar Tong is designed for handling of slab and T-bars by grabbing in the end section. The TC units has a hugh range and can normally handle the complete range with one unit. The TC units has low height and leaves very small handling marks.

With the TC Slab Bar Tong you may handle slabs and T-bars vertically and horizontally using the same unit.

Advantages:

• Huge range

• Low height

• Extra mechanical safety system available

• Reliable in operation – low maintenance.

• Service and maintenance system available

• Hugh number of systems in operation

Slab Bar Tong Low Weight

The TC low weight Slab Bar Tong has a very compact and low weight design. The tong can only be used during stripping operation—no horizontal handling. This unit grabs the slab at the long side, but handling marks are very limited.

The rotating clamping arm system gives a very soft handling with reduced stress to the crane system during lay down operation.

Advantages:

• Huge range

• Low weight

• Extra mechanical safety system available

• Reliable in operation – low maintenance.

• Service and maintenance system available

• Compact and easy to handle

The TC Billet Tong is designed for handling of extrusion billets from DC casting pit to lay down position. It is normally possible to handle all dimensions with the same unit without any readjustment.

The tong may also be used for handling of square billets, oval billets, T -bars and slabs.

Advantages:

• All diameters with the same unit with—no readjustment

• No handling marks after cropping

• One man operation

• Safe operation

• Reliable—low maintance

TC Engineering AS has recently upgraded its product range with a new system for 100 % ultrasonic testing of extrusion billets.